Culver City-based Azure Printed Homes is ramping up production, recently opening a factory in Culver City and having been chosen to create 14 prefabricated homes for Oasis Development, a project owned by Ken Bagga, who also owns Oasis Inn & Suites in Ridgecrest.

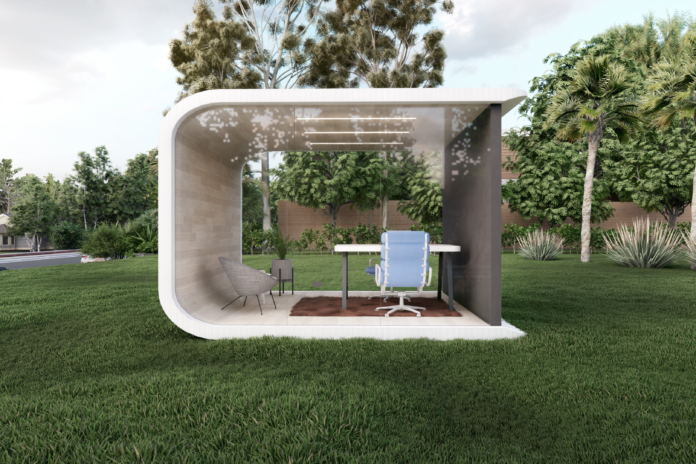

Azure uses recycled plastic 3D-printing technology to create buildings. The company is starting with accessory dwelling units and studios with plans to expand to larger projects.

Founded in 2019 by Gene Eidelman and Ross Maguire, Azure can build projects 70% faster and 30% cheaper than other construction methods, according to the company.

By using recycled materials, Chief Executive Maguire said, the projects are also more environmentally friendly than traditional construction projects.

“We want to be innovative and timely and trustworthy,” Maguire said. “We’ve taken steps over the last two and a half years and in the last year have really focused on 3D printing with recycled materials and are really excited to release it.”

Azure also does traditional development projects. Maguire said clients consistently ask for projects to be done faster and that 3D printing enables the company to print and deliver buildings quickly. A small ADU or studio, he said, can print in less than a day.

“It’s a crazy level of efficiency in terms of time and cost,” he said, adding that traditional “construction is still in the Dark Ages” when it comes to the process and how long it takes to get things built.

“It’s an industry that’s ready for a new way of thinking and a new way of producing homes, and we feel like with the demand for houses and the housing crisis, there needs to be a new, faster, less expensive and environmentally friendly option,” Maguire said.

Azure uses robotic arm printers to 3D print its creations.

The deal with Oasis Development was announced this month. Oasis is planning to start site work on its development in August. Azure will deliver 14 homes to create the community in September.

“Oasis is pleased to announce our partnership with Azure to deliver 3D-printed modular homes to Ridgecrest,” Bagga, chief executive of Oasis, said in a statement. “We have been actively researching several potential prefab manufacturers for this particular project for several years. We finalized our current plans for this development with Azure’s input. Their expertise has accelerated our learning around their innovative products and processes. Now that our agreement is signed, we look forward to seeing these new modern homes being manufactured by Azure Printed Homes and installed in our Ridgecrest development.”

The project is the first community of durable homes to be created entirely by 3D printing using waste materials, according to Azure. Azure, formerly based in Mar Vista, announced the opening of a 15,000-square-foot factory in Culver City, which also serves as its headquarters, earlier this month.

Azure is accepting pre-orders for ADUs and backyard studios. It plans to begin 3D printing full-sized homes by 2023 and eventually taller structures.

“We have ambitions to maintain modular construction so we could be printing smaller modules … that can be connected to create larger homes and with the ambition of stacking them vertically as well,” Maguire said. “We see backyard studios and the ADU industry as a good starting point to prove out the potential.”

The company, which is currently focused on Southern California, also hopes to open manufacturing locations in other regions and expand to other cities.